What to do when the solder wire is slow

2019-12-25

First of all, we need to understand that when soldering, it depends on the intermediate flux to work together. From a detailed point of view, the focus is on the active agent in the flux. The rosin in the flux is only the carrier of the active agent. The combination of active agents and other special ingredients makes this a flux. In the soldering process, the role of the flux is to remove the oxide of the object to be soldered, enhance the flowability of the solder wire, and make the solder wire and the weldment tightly adhere together. The function of the flux must be well understood.

Therefore, when soldering, it is found that the soldering speed of the solder wire is slow, and the beads will stick to the tip of the soldering iron. We should take the initiative to consider the following issues.

1. What is the material of the weldment and is it suitable for use with such solder wire and flux? Choosing a suitable flux is a major factor in soldering.

2. The same type of flux has different effects, will it affect the speed of soldering and can it be soldered?

3. Is the content of flux in the solder wire sufficient? The content of flux will also affect the tin loading. The larger the content, the easier and faster the tin loading, but at the same time it will generate a large amount of smoke.

4. Is the temperature of the electric soldering iron insufficient? If the heat provided by the electric soldering iron is insufficient, even the solder wire cannot be melted, then it is easy to talk about tin.

According to the thought of these problems, or this factor that may lead to slow soldering speed.

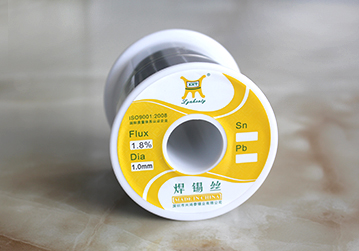

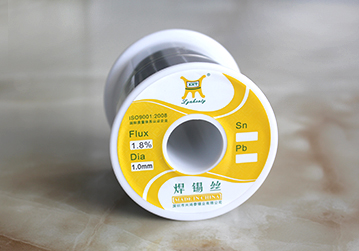

Shenzhen Xinghongtai Tin Industry Co., Ltd. is a professional solder wire manufacturer. It has specialized in the research and development of solder wire for 12 years, and provides solder wire, lead-free solder wire, lead solder wire, solder wire, solder bar and solder wire of different specifications.

Therefore, when soldering, it is found that the soldering speed of the solder wire is slow, and the beads will stick to the tip of the soldering iron. We should take the initiative to consider the following issues.

1. What is the material of the weldment and is it suitable for use with such solder wire and flux? Choosing a suitable flux is a major factor in soldering.

2. The same type of flux has different effects, will it affect the speed of soldering and can it be soldered?

3. Is the content of flux in the solder wire sufficient? The content of flux will also affect the tin loading. The larger the content, the easier and faster the tin loading, but at the same time it will generate a large amount of smoke.

4. Is the temperature of the electric soldering iron insufficient? If the heat provided by the electric soldering iron is insufficient, even the solder wire cannot be melted, then it is easy to talk about tin.

According to the thought of these problems, or this factor that may lead to slow soldering speed.

Shenzhen Xinghongtai Tin Industry Co., Ltd. is a professional solder wire manufacturer. It has specialized in the research and development of solder wire for 12 years, and provides solder wire, lead-free solder wire, lead solder wire, solder wire, solder bar and solder wire of different specifications.